Content

Introduction

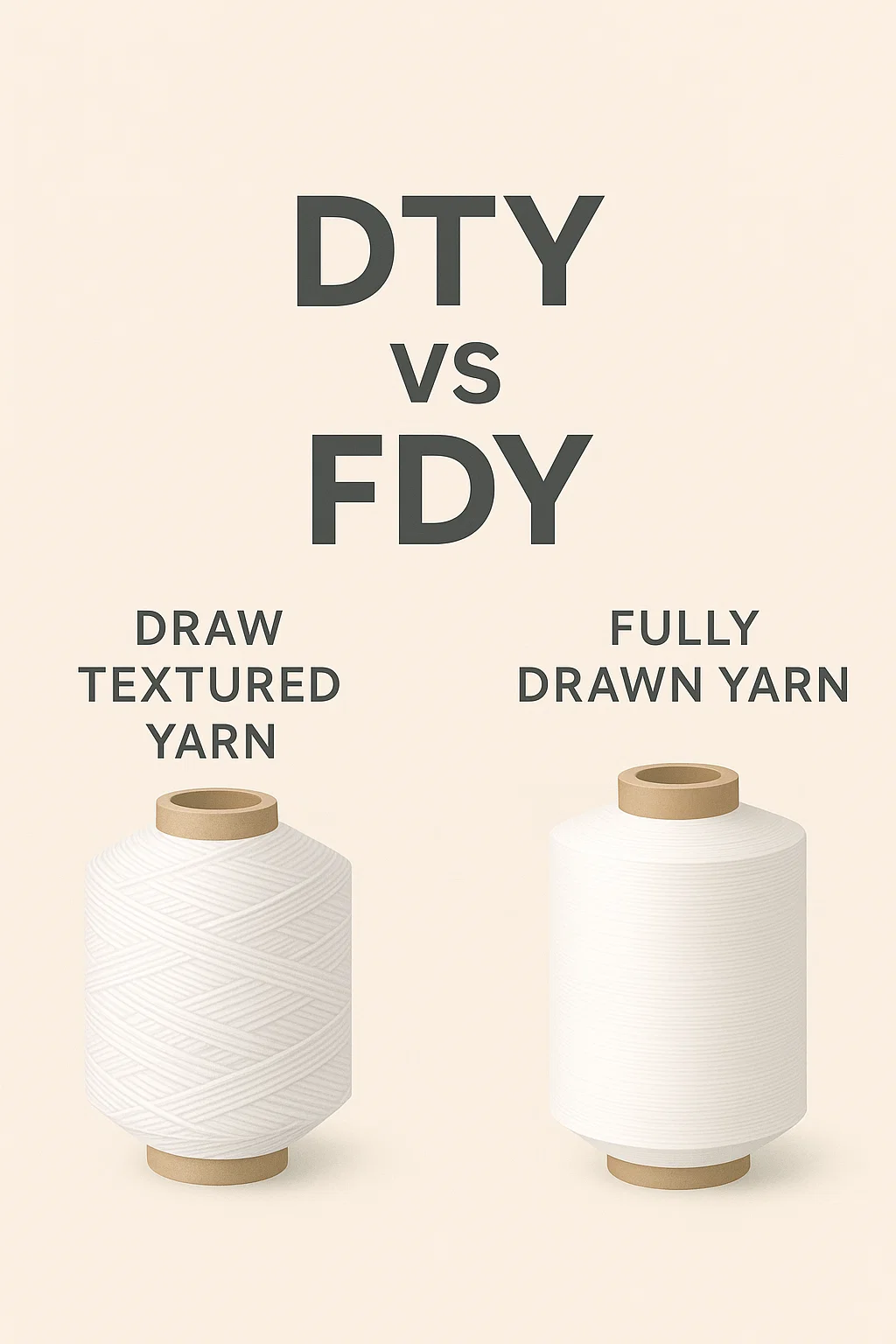

In the world of textiles, the choice of yarn plays a crucial role in determining the quality, feel, and durability of the final fabric. Two commonly used types of yarn are Draw Textured Yarn (DTY) and Fully Drawn Yarn (FDY). While both are made from synthetic fibers like polyester and nylon, they have distinct characteristics that make them suitable for different applications in the textile industry.

Understanding the differences between DTY and FDY is essential for manufacturers and designers alike, as these yarns impact everything from fabric texture and elasticity to strength and durability. This article delves into the key differences, properties, and applications of these two yarn types, helping you make an informed decision on which is best suited for your next project, whether it's for fashion, home textiles, or industrial applications.

What is DTY (Draw Textured Yarn)?

Draw Textured Yarn (DTY) is a type of synthetic yarn that undergoes a specialized manufacturing process to enhance its texture, elasticity, and overall appearance. The "textured" aspect refers to the process of introducing crimp, curl, or wave into the yarn, which gives it a soft, bouncy, and fuller feel. This makes DTY particularly popular in applications that require softness, flexibility, and a fabric with more volume.

Manufacturing Process of DTY:

-

Drawing:

The process begins with drawing, where the filament fibers are stretched to align them in a uniform direction. This step increases the tensile strength of the yarn, ensuring that it can withstand mechanical stress during its use in textiles. -

Texturing:

The defining step in the creation of DTY is texturing. There are various techniques for this, but the two most common methods are:-

Air Jet Texturing: Uses high-pressure air to twist the fibers together, creating a natural, soft, and fluffy texture.

-

False Twist Texturing: Involves twisting the fibers under heat, which gives the yarn a more defined crimp and a slightly stiffer texture than air jet texturing.

These methods introduce a higher degree of elasticity and bulk to the yarn, making it suitable for fabrics that require flexibility and comfort, such as sportswear and casual wear.

-

-

Winding:

Finally, the textured yarn is wound onto spools, ready to be used in weaving, knitting, or other textile production processes.

Key Properties of DTY:

-

High Bulk and Elasticity: The texturing process increases the yarn’s bulk, giving it a thicker, fuller feel, while also making it highly elastic. This allows fabrics made from DTY to stretch and recover easily, making them ideal for activewear and comfortable clothing.

-

Soft Texture and Good Insulation: DTY fibers retain a soft, plush feel due to their textured nature. This makes them an excellent choice for fabrics that require a smooth touch against the skin, such as bed linens, sportswear, and upholstery.

-

Resilience and Wrinkle Resistance: Thanks to its crimped structure, DTY yarn has great resilience, meaning it returns to its original form after being compressed. This characteristic helps fabrics made from DTY resist wrinkles and maintain their shape over time.

Applications of DTY:

DTY is commonly used in a variety of textile applications, including:

-

Apparel:

-

Sportswear: The elasticity and moisture-wicking properties of DTY make it ideal for activewear like gym clothes, leggings, and yoga pants.

-

Casual Wear: Soft, breathable fabrics like T-shirts, sweatshirts, and fleece jackets often utilize DTY for a comfortable, relaxed fit.

-

-

Home Textiles:

-

Upholstery: The durability and plush texture of DTY make it a popular choice for soft furnishings like sofas, cushions, and throw blankets.

-

Curtains: Its softness and drapability make DTY perfect for home décor items like curtains and drapes.

-

-

Industrial Fabrics:

-

DTY is also used in more technical applications, such as in the production of industrial fabrics, where its strength, elasticity, and bulk come into play.

-

DTY’s combination of softness, resilience, and versatility makes it an essential yarn in the textile industry, especially for products that require both comfort and durability.

What is FDY (Fully Drawn Yarn)?

Fully Drawn Yarn (FDY) is a type of synthetic yarn that is manufactured through a process of drawing and spinning to create a smooth, strong, and lustrous filament. Unlike Draw Textured Yarn (DTY), FDY is not subjected to any texturing process. As a result, FDY maintains a sleek, smooth appearance and high strength, making it ideal for applications where durability, smoothness, and colorfastness are crucial.

Manufacturing Process of FDY:

-

Spinning:

The process starts with the extrusion of synthetic polymer, typically polyester or nylon, which is then spun into continuous filaments. This initial stage forms the basic structure of the yarn. -

Drawing:

The spun filaments are drawn, or stretched, to align the molecules within the yarn, which enhances its strength and increases its tenacity. This step is critical for FDY, as it helps achieve its smooth texture and high strength. The drawing process also improves the yarn's uniformity and reduces the risk of defects. -

Winding:

After drawing, the yarn is wound into large bobbins or spools, ready to be processed into fabrics. The winding process ensures that the yarn is easy to handle and can be used in further textile production, such as weaving, knitting, or embroidery.

Key Properties of FDY:

-

Smooth and Lustrous Appearance:

FDY’s smooth finish gives fabrics made from this yarn a glossy, elegant look. Its lustrous surface is highly valued in textiles that require a shiny, refined finish, such as high-end fashion garments and luxury home textiles. -

High Strength and Durability:

The drawing process imparts excellent tensile strength to FDY, making it more durable than many other types of yarn. FDY fabrics are strong and resilient, which is why FDY is often used in products that demand long-lasting performance and resistance to wear and tear. -

Excellent Colorfastness:

FDY’s smooth surface allows dyes to bond more evenly, resulting in vibrant, consistent colors that are less likely to fade with washing and use. This property makes FDY ideal for textiles where color retention is essential, such as embroidered fabrics or technical textiles.

Applications of FDY:

FDY is primarily used in applications that require a combination of strength, luster, and a smooth finish. Common uses include:

-

High-End Fabrics:

-

Sarees and Dress Materials: The smoothness and shine of FDY make it a popular choice for luxury garments like sarees, evening dresses, and other formal attire.

-

Fashion Garments: FDY is often used in the production of high-quality fashion fabrics, such as satin, taffeta, and chiffon, which require a shiny and smooth texture.

-

-

Technical Textiles:

-

Due to its strength and durability, FDY is frequently used in the production of technical textiles, such as geotextiles, automotive fabrics, and industrial materials. These textiles often require materials that can withstand stress while maintaining a refined look.

-

-

Embroidery Threads:

FDY’s high strength, smoothness, and excellent colorfastness make it an ideal choice for embroidery threads, which need to retain their color and integrity even through multiple washings.

FDY is a versatile and essential yarn in the textile industry, known for its durability, smooth finish, and ability to hold vibrant colors. It is the go-to yarn for products that require a sleek, professional appearance, combined with the strength to endure regular use.

Key Differences Between DTY and FDY

While Draw Textured Yarn (DTY) and Fully Drawn Yarn (FDY) are both synthetic yarns derived from similar processes, they differ significantly in terms of their manufacturing processes, properties, and applications. Understanding these differences is crucial when choosing the right yarn for specific textile products.

1.Manufacturing Process:

-

DTY:

DTY undergoes an additional texturing process, which introduces crimp, curl, or wave into the yarn. This texturing process can be done through methods like air jet texturing or false twist texturing, which gives the yarn its characteristic bulk and elasticity. The yarn is drawn to a certain strength before texturing is applied, which is the key factor that distinguishes it from FDY. -

FDY:

FDY, on the other hand, is fully drawn during the manufacturing process. The filaments are stretched (drawn) to enhance their strength but are not subjected to any texturing. As a result, FDY maintains a smooth, lustrous surface. There is no additional process that alters the yarn’s texture once it is drawn, resulting in a finer, more uniform appearance compared to DTY.

2. Texture and Appearance:

-

DTY:

Due to the texturing process, DTY has a softer, bulkier texture with more elasticity and volume. The yarn’s surface may be crimped or twisted, giving it a more “fuzzy” or “fluffy” appearance. Fabrics made from DTY are often softer to the touch and have a more matte or semi-matte finish. -

FDY:

FDY has a smooth, shiny, and lustrous appearance. Its surface is sleek and even, making it ideal for creating fabrics that require a glossy or high-end look. The yarn’s strength and fine finish give it a more refined, formal appearance, which is why FDY is often used in luxury textiles and technical fabrics.

3. Elasticity and Bulk:

-

DTY:

One of the standout characteristics of DTY is its high elasticity and bulk. The texturing process gives the yarn a bouncy, stretchy feel, making fabrics made from DTY very comfortable and flexible. This increased elasticity is especially beneficial in applications like sportswear and activewear. -

FDY:

FDY, while strong and durable, is less elastic compared to DTY. It is designed to be smooth and strong rather than bulky or elastic. FDY’s smoothness makes it less “stretchy,” which can be a disadvantage in applications where flexibility and stretch are important.

4. Strength and Durability:

-

DTY:

DTY is generally less strong than FDY due to its textured structure. While it has a good level of resilience and durability, its elasticity and bulk can sometimes make it more prone to wear and tear over time. It’s great for fabrics that need to stretch and recover, but it may not be the best choice for heavy-duty applications. -

FDY:

FDY is known for its high strength and durability. The fully drawn process ensures that the yarn has superior tensile strength, making it ideal for applications that require resilience and long-lasting performance, such as technical textiles, industrial fabrics, and luxury fashion.

5. Applications:

-

DTY:

DTY’s bulk, elasticity, and softness make it ideal for fabrics that require flexibility, comfort, and volume. Common applications include:-

Sportswear (leggings, activewear, performance wear)

-

Casual apparel (T-shirts, fleece jackets)

-

Home textiles (curtains, upholstery, bedding)

-

-

FDY:

FDY’s smooth, lustrous finish and strength make it perfect for high-end and durable textiles. It is commonly used in:-

Luxury fabrics (sarees, evening gowns, dress materials)

-

Technical textiles (automotive fabrics, industrial textiles)

-

Embroidery threads and high-end fashion garments (satin, taffeta, chiffon)

-

6. Softness vs. Strength:

-

DTY:

DTY is softer to the touch due to its textured structure. It is often chosen for its comfort and plush feel, making it ideal for products that will be worn close to the skin or need to be soft and flexible. -

FDY:

FDY, while durable and strong, is less soft than DTY. The smoothness and lack of texture make it more rigid, which may be less comfortable for garments that require flexibility and softness. However, its strength makes it ideal for textiles that need to withstand rigorous conditions.

7. Cost:

-

DTY:

Generally, DTY can be more cost-effective than FDY because the texturing process is less complex than the fully drawing and winding process required for FDY. However, this can vary depending on the quality of the yarn and the specific texturing method used. -

FDY:

Due to its more complex manufacturing process and higher strength, FDY is typically more expensive than DTY. The smooth finish and durability it provides come at a premium, especially for luxury and industrial applications.

|

Feature |

DTY (Draw Textured Yarn) |

FDY (Fully Drawn Yarn) |

|

Manufacturing Process |

Includes drawing followed by texturing (air jet or false twist), adding bulk and elasticity. |

Only undergoes drawing; smooth and uniform yarn without any texturing. |

|

Texture & Appearance |

Soft, bulky, elastic texture with possible crimp or twist. |

Smooth, lustrous, and uniform finish, giving a refined look. |

|

Elasticity & Bulk |

High elasticity and bulk, ideal for fabrics that require stretch and recovery. |

Lower elasticity, smooth and uniform yarn, more rigid. |

|

Strength & Durability |

Generally lower strength, suitable for applications needing softness, but less durable. |

High strength and durability, ideal for long-lasting performance. |

|

Applications |

Sportswear, casual wear, home textiles (curtains, upholstery), industrial fabrics. |

High-end fabrics (sarees, dress materials), technical textiles, embroidery threads. |

|

Softness & Comfort |

High softness, ideal for skin contact fabrics like sportswear and casual clothing. |

Less soft, more rigid, suited for formal and high-end fabrics. |

|

Colorfastness |

Lower colorfastness, better suited for short-term use or low-friction applications. |

High colorfastness, ideal for fabrics that need to retain vibrant colors over time. |

|

Cost |

More cost-effective, suitable for mass production. |

More expensive, ideal for high-end, durable, and glossy textile applications. |

Pros and Cons of DTY and FDY

Understanding the advantages and disadvantages of DTY (Draw Textured Yarn) and FDY (Fully Drawn Yarn) is crucial for choosing the right yarn for a specific application. Here’s a breakdown of the pros and cons of each type:

DTY (Draw Textured Yarn)

Pros:

-

Softness and Comfort: DTY is known for its soft texture, making it ideal for fabrics that need to feel comfortable against the skin, such as sportswear, activewear, and casual clothing.

-

Elasticity: The texturing process gives DTY excellent elasticity, which is perfect for stretchable fabrics like leggings and yoga pants.

-

Bulk and Volume: DTY adds bulk to fabrics, making it a good choice for fluffy or voluminous materials like fleece jackets and upholstery.

-

Wrinkle Resistance: Thanks to its crimped structure, DTY is naturally more wrinkle-resistant, which helps maintain the fabric's appearance over time.

-

Versatility: The ability to produce various textures through air jet or false twist methods makes DTY versatile for use in sportswear, home textiles, and even industrial fabrics.

Cons:

-

Less Durability: DTY is generally less durable than FDY because the texturing process weakens the fibers slightly. It may wear out faster in high-stress applications.

-

Lower Strength: While it has good elasticity, DTY doesn’t offer the same tensile strength as FDY, making it less suitable for applications requiring high resistance to physical stress.

-

Lower Colorfastness: The texture of DTY may affect dye absorption, which can result in slightly lower color retention compared to FDY, especially with prolonged washing.

FDY (Fully Drawn Yarn)

Pros:

-

High Strength and Durability: FDY is stronger and more durable than DTY, making it an excellent choice for industrial textiles, automotive fabrics, and other applications that require long-lasting performance.

-

Smooth and Lustrous Appearance: FDY maintains a glossy, smooth finish, ideal for luxury fabrics, fashion garments, and high-end home textiles like sarees and evening dresses.

-

Excellent Colorfastness: The smooth surface of FDY allows for better dye bonding, resulting in stronger color retention even after repeated washes. This makes it ideal for color-sensitive fabrics.

-

Superior Tensile Strength: Due to the fully drawn process, FDY exhibits high tensile strength, making it ideal for fabrics that undergo significant stress or wear, such as technical textiles and embroidery threads.

Cons:

-

: FDY is less elastic than DTY, which can make fabrics feel stiffer and less flexible, especially for products like activewear that require a high degree of stretch. -

Higher Cost: Due to its more complex manufacturing process and higher durability, FDY is more expensive than DTY. This can make it less cost-effective for certain mass-produced products.

-

Less Softness: The smooth, fully drawn nature of FDY makes it less soft compared to DTY, which may be a disadvantage for fabrics that need to be soft and comfortable, such as casual wear.

Popular Products Made from DTY and FDY

Both DTY (Draw Textured Yarn) and FDY (Fully Drawn Yarn) are used in a variety of products across different sectors, with each type of yarn excelling in specific applications due to their unique properties. Here’s a breakdown of the most popular products made from DTY and FDY:

Popular Products Made from DTY:

-

Sportswear & Activewear:

-

Yoga Pants

-

Leggings

-

Gym Clothes

-

Sports Jerseys

DTY’s elasticity and softness make it a favorite for activewear, providing comfort and flexibility needed for physical activities.

-

-

Casual Wear:

-

<>T-Shirts

-

Sweatshirts

-

Fleece Jackets

DTY adds bulk and softness, making these garments cozy and perfect for daily wear.

-

-

Home Textiles:

-

Curtains

-

Upholstery Fabrics

-

Bedding (Blankets, Comforters)

The softness and bulk of DTY also make it ideal for soft furnishings and home décor items that require a plush, comfortable feel.

-

-

Industrial Fabrics:

-

Seat Covers (Automotive)

-

Safety Apparel

DTY is used in certain industrial textiles for its resilience, especially when comfort is needed in tough working conditions.

-

-

Knitted Fabrics:

-

Sweaters

-

Hoodies

DTY is commonly used in knitted fabrics due to its elasticity and ability to stretch and recover easily, adding comfort and warmth to knitted apparel.

-

-

Swimwear and Lingerie:

-

Swimwear

-

Underwear

Due to its softness, elasticity, and comfort, DTY is commonly used in swimwear and lingerie that requires flexibility and a soft feel against the skin.

-

Popular Products Made from FDY:

-

High-End Fashion Fabrics:

-

Evening Gowns

-

Dresses

-

Sarees

FDY’s smooth finish and luster make it ideal for luxury fashion fabrics that require a glossy, polished look.

-

-

Technical Textiles:

-

Automotive Fabrics (e.g., seat covers, airbags)

-

Geotextiles (used in construction and landscaping)

-

Protective Workwear

FDY’s strength and durability make it a prime choice for technical fabrics that need to withstand heavy use and provide long-term performance.

-

-

Embroidery Threads:

-

Thread for Embroidery

FDY is used to produce embroidery threads due to its strength and colorfastness, ensuring vibrant, long-lasting colors in embroidered designs.

-

-

Home Textiles (Premium):

-

Luxury Curtains

-

High-End Bedding (e.g., silk-like sheets and duvet covers)

FDY is often used in premium home textiles due to its smooth texture and luster, offering a high-end, elegant finish for home décor.

-

-

Outdoor and Sports Fabrics:

-

Raincoats

-

Windbreakers

FDY’s strength and colorfastness make it a great choice for technical outdoor fabrics that need to endure exposure to the elements.

-

-

Fashion Accessories:

-

Ties and Scarves

-

Sashes and Belts

FDY’s smooth surface and lustrous finish make it ideal for accessories that require a high-quality look and feel.

-

-

Lingerie and Underwear (Luxury):

-

Luxury Lingerie

-

High-End Bras and Panties

FDY is used in premium lingerie due to its strength, smoothness, and colorfastness, making it a top choice for high-quality undergarments.

-

How to Choose Between DTY and FDY

Choosing between DTY (Draw Textured Yarn) and FDY (Fully Drawn Yarn) depends on several factors, including the end-use of the fabric, desired properties (such as elasticity, strength, or softness), and cost considerations. Here’s a guide to help you make the best choice:

1. Consider the End-Use of the Fabric:

-

DTY:

If the fabric is intended for sportswear, activewear, or casual clothing, where elasticity, softness, and comfort are key, then DTY is often the better choice. It’s also ideal for products like upholstery, home textiles (curtains, cushions), and knitted fabrics where bulk and resilience are important. -

FDY:

If the fabric will be used for high-end fashion, technical textiles, or luxury home décor, FDY is the more suitable option. Its smooth finish, strength, and colorfastness make it ideal for premium fabrics, embroidery threads, and industrial applications that require durability and a polished appearance.

2. Evaluate the Desired Properties:

-

Elasticity and Bulk:

-

If the fabric needs to stretch, recover, or maintain a voluminous texture, DTY is the preferred choice due to its elasticity and bulk. This is particularly useful for activewear, sportswear, and fleece fabrics.

-

-

Smoothness and Luster:

-

If you need a smooth, lustrous surface for luxury fashion fabrics or premium textiles, FDY excels in this area. The high gloss and fine finish are perfect for creating fabrics that require a refined look (e.g., evening gowns, sarees).

-

-

Strength and Durability:

-

If strength and durability are paramount, FDY is the better choice. Its high tensile strength and long-lasting performance make it suitable for products like technical textiles, automotive fabrics, and industrial uses.

-

-

Softness and Comfort:

-

If you prioritize softness and comfort, particularly for products that will be worn close to the skin (like lingerie, casual wear, and home textiles), DTY is more likely to meet your needs due to its soft texture.

-

3. Cost Considerations:

-

DTY:

Generally, DTY is more cost-effective due to its simpler manufacturing process. The texturing step adds bulk and elasticity without significantly increasing the production cost. Therefore, DTY is a better choice for mass production or when you’re working with a budget. -

FDY:

FDY tends to be more expensive because its manufacturing process is more complex and requires additional steps to draw and wind the fibers. However, its strength, durability, and luster make it worth the extra cost for premium applications or high-end fabrics that demand longevity and a sophisticated finish.

4. Consider the Fabric’s Intended Lifespan:

-

DTY:

Fabrics made from DTY are more suited for shorter-term use, such as in casual clothing or home textiles, where comfort and flexibility are more important than long-term durability. -

FDY:

If the fabric is intended for use in long-lasting applications, such as industrial fabrics, automotive interiors, or luxury fashion, FDY is the more appropriate choice due to its greater durability and resilience.

5. Assess the Fabric’s Aesthetic Requirements:

-

DTY:

If you’re looking for fabrics with a soft, matte appearance, DTY is ideal. It gives a comfortable, casual look, making it suitable for products like activewear, upholstery, and knitted garments. -

FDY:

If the fabric requires a glossy, polished finish, such as evening wear, formal suits, or premium home textiles, FDY will provide the desired aesthetic with its high sheen and luxurious finish.

6. Consider Environmental Factors:

-

DTY:

Fabrics made from DTY can provide better thermal insulation due to their bulk and elasticity, making them ideal for winter clothing, outerwear, and insulating textiles. -

FDY:

FDY fabrics, with their smooth surface, are more suited for technical fabrics used in high-performance environments, where strength, resistance to wear, and longevity are critical.

عربى

عربى